Every day, millions of plastic security seals with different designs are made. For a business person, choosing the right one can be an issue. This blog post should make the process easier while informing you of some of the crucial elements of cable seals. You will also learn what to look out for in the market when deciding the right cable seal to safeguard your products.

Different experts have been on the frontline of manufacturing security seals for more than 30 years. Such individuals are known for working with market leaders across different sectors.

In a nutshell, therefore, it is easy to understand just how to make these materials using the ideal plastic. As experienced manufacturers, it is important to know the aspects of a good cable plastic material.

1. Quality – while this sounds like a cliché, if you read on, you shall see the invaluable point to it. Quality does not just imply the type of seal and how neat it is.

When it comes to quality, you should look at the plastic type used to manufacture the seal.

2. Locking Mechanism- most of the nice plastic seals come with a locking mechanism in order to help in making sure that the plastic seal has significant pull strength.

Besides, a metal locking system has a preventive measure for boiling water attacks as well as freeze attacks.

In many instances, this often allows for a better as well as stronger plastic seal in order to enhance the security of commodities.

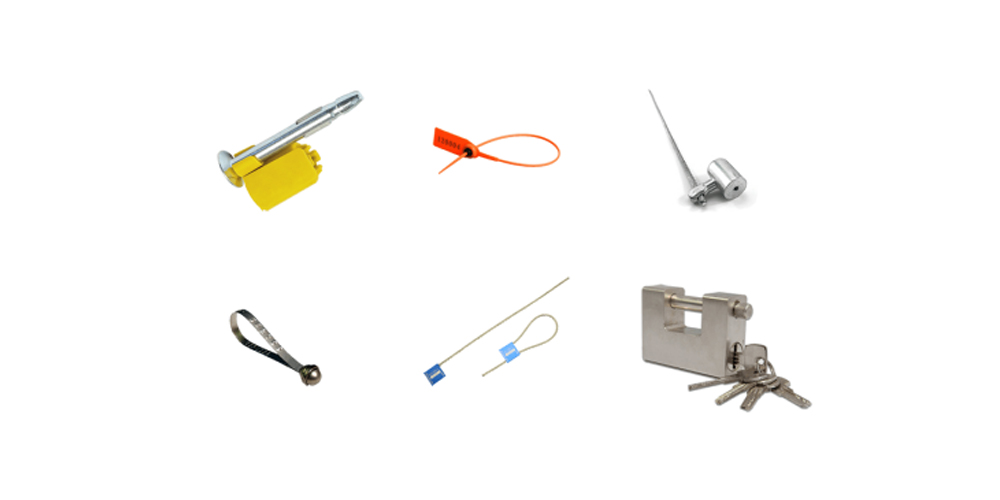

3. Think of Diversification- as stated earlier on, experts work with several organizations as well as industries but with various requirements and additional applications. That is why companies manufacture seals to make it possible for them to be used on a variety of application types.

In essence, many experts believe the fact that when choosing a security sealing cable to guard your products, you need to make sure that the seal has excellent quality plastic with a strong locking mechanism.

That said, it happens that most experts in the industry sell quality seals. There is, therefore, a belief that these devices can cater to all applications demanding high-quality seals.

Appropriate handling and usage

Nothing beats the feeling of working with a strong plastic material to create a cable seal. And as with any other seal, proper control and inspection are essential. Go through the industrial recommended practices in this blog post for more constructive details.

Note, to insert a seal; then the cable should be placed parallel to itself and straight into the hole on the side with an extended attachment from the body of the lock.

It would help if you had a firm push to achieve this. When locking a cable seal, it must be pulled without damaging the device it is appended to. Many seals come with a cable that can fray when cut.

For that reason, it is impossible to reuse it, especially after cutting. Cable seals that do not fray right after cutting should be cut off after sealing.

Final Thoughts

You should note that when removing the seals of the cable, you need to utilize a quality bypass of sheer. For medium cables, experts provide a reliable cutter to make your work easier. Extended bypass cutters may be found at different electrical supply as well as industrial tool supply retailers.