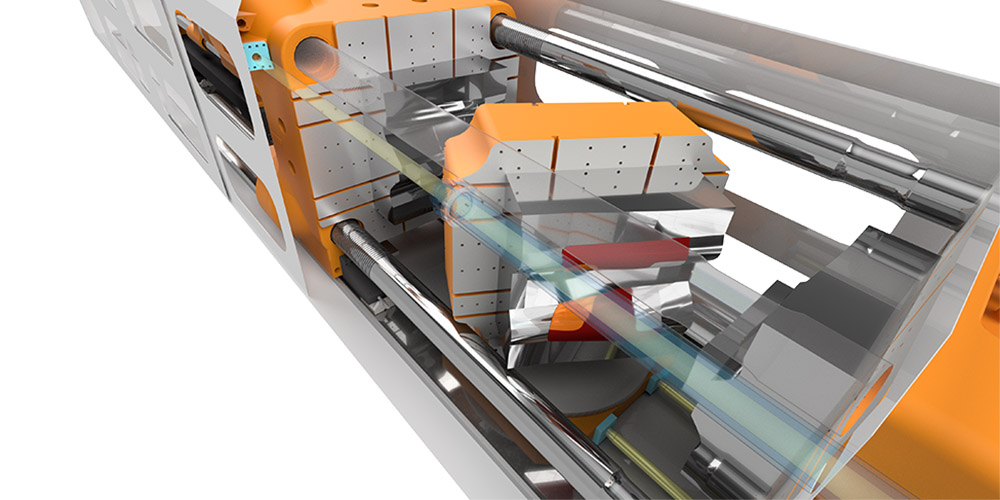

Injection molding deals with the injection of liquid into molds to make parts that can be used to create larger materials. They can either produce these parts through rapid mold or regular molding process.

Molds can sometimes be expensive especially if an expensive injection molding process was used to produce them.

Certain factors can affect the price of injection molding. Understanding them is an important key to running a profitable manufacturing injection molding business. Let’s get right into it!

Factors that can affect the cost of injection molding?

Usually, a single, small cavity injection mold costs around $1,000 to $5,000. Complex or large molds, on the other hand, can cost around $80,000 or even more. So, what can affect the price of injection molding?

1. Complexities of part

First, consider the complexity of your molds. That’s because the complexity of your design can greatly influence the cost of your injection mold, as it is with a lot of engineering machines.

If the injection parts have a lot of undercut components, you are bound to pay more for the required tooling. Similarly, if the corners are sharp, the price of tooling will also be high.

2. Surface finish

The types of surface finish you want to a large extent determine the cost of your injection mold. This means that if you want a high-quality surface finish, you will pay more because a bulk of the work is manually done.

On the other hand, the surface finish done with a machine will not cost a lot. That’s because it’s much easier to do, unlike hand finishing that consumes a lot of time and effort.

3. Kind of steel

There is a variety of steel that can be used for different occasions, but they don’t all cost the same amount. To find out the cost, you need to understand the type of steel you’re dealing with.

4. Number and size of cavities.

While working with an injection mold manufacturer, understand that the size and number of cavities involved go a long way to determine the cost.

For size, you should know that the plastic size parts that will be produced are directly proportional to the size of the mold. Large molds will need a bigger amount of building space. They will also need the injection molder to have expensive tools to work on them.

5. The mold supplier’s location in China

Most injection molding companies in China have a different cost of molding, unlike other parts of the world. Often, the costs are overhead and they always show up in different ways.

However, the location of the Chinese company will determine if the cost of injection molding will be higher or lower. While your injection molder may not let you know this, you must make your findings.

Different Chinese provinces have a specific minimum wage. So, this is often factored in when determining the cost of making a prototype.

Final Thoughts

In summary, you must not go into the market to buy an injection molding machine without carefully analyzing the costs using the factors In this guide.

You may spend a lot of time analyzing these factors but rest assured that you will be able to save enough money at the end of the day.